Tesla’s Manufacturing Efficiency

Michigan-based engineering firm Caresoft Global Technologies believes that Tesla is about to drastically decrease assembly times and floor space in its factories - by as much as 30%.

Caresoft is a firm that specialises in helping their clients cut costs and improve efficiency using physical and digital benchmarking - and during a recent interview with Automotive News, it was revealed that the company’s forecast for Tesla in the next couple of years was very positive.

Specifically, Caresoft’s experts believe that assembly times will be reduced by 25% once Tesla’s new upgrades come online, and further efficiency measures will result in the company using 30% less floor space in their factories.

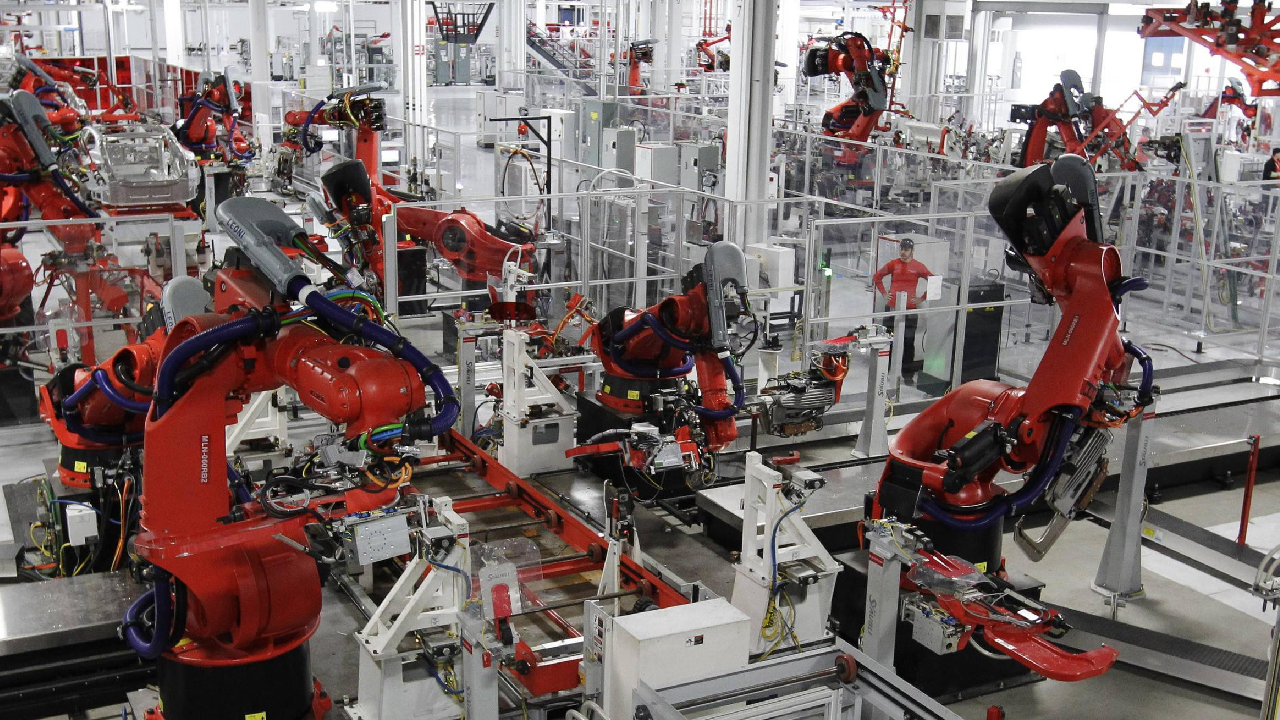

The upgrades and measures Caresoft is citing here were largely unveiled during Tesla’s Investor Day Event back in March. Aside from reducing part counts in their vehicles like the Model Y and Model 3, Tesla was very excited to show how they were going to be streamlining the whole manufacturing process of their vehicles - changing up timing and build stages to make more efficient choices with the space they were using and the ability for people and robots to work at the same time.

Adding on to that, Tesla announced their new factory in Mexico at that same event, as well as a new model of Tesla car being designed. With all this happening at the same event, it’s hard to not draw the conclusion that GigaMexico is going to be one of the first places Tesla is really going to be able to test their new manufacturing philosophy.

But a single presentation isn’t something that an engineering firm builds predictions on, which means Caresoft has been watching Tesla’s recent work.

It’s probably easiest to see all the new technology Tesla is using with the Cybertruck. Those 9000 ton gigapresses alone would be enough to assume that the company is going to be more efficient with their newer vehicles at least.

And that new refinery that just broke ground in Corpus Christi, Texas would be a solid indicator of Tesla’s future with their battery ecosystem. The company is planning out a web of clean lithium refining, cathode and battery production, and recycling that will begin to allow Tesla to more directly control one of the most important pieces of their manufacturing puzzle.

Digging even further shows that Tesla has been making sweeping changes to their existing Gigafactories - with battery production lines being added to GigaTexas, production lines being moves around at Fremont to make room for more vehicle assembly lines, and expansions to GigaNevada, and GigaBerlin.

If the efficiencies Tesla talked about at Investor Day are really going to be freeing up space, then the expansions the company is working through right now mean that Tesla is about to really scale up their production.

When Caresoft made their prediction about efficiency, they were seeing all of this happening just like we were, and predicted that Tesla would be able to lower their investment in their own factories by as much as 30%. Given that we know Tesla is actively hunting for another Gigafactory location, that part of Caresoft’s prediction won’t likely be true for some time - but with the ramp-up in production that will come from the increased space and efficiency, it’s hard to think Tesla won’t be making way more money.

If anything, Caresoft might have been too conservative.